Centrifugal compressor

The Centrifugal compressor is to increase the pressure of the gas, and the gas passes through the impeller due to the high-speed rotation of the impeller, the gas is subjected to the effect of centrifugal force to produce pressure. In recent years, with the promotion of new metallurgical technology, the expansion of the scale of petrochemical enterprises and the rapid development of new coal chemical industry, green coal power and other industries, the number and scale of air separation equipment requirements are increasing. The large scale of air separation equipment is the direction of development. In order to cooperate with the market development, Hubei Double sword from 2002 began to devote to the research of air separation compressor unit, in order to ensure the advanced nature and reliability of the unit, we with many domestic scientific research institutions and efficient technical cooperation, developed an energy-saving and environmental protection double sword series supercharger, mainly used in petroleum, chemical industry, metallurgy, coal, medicine, air separation, power, textile and other fields.

Craftsmanship and Quality

Lean design Energy efficient

Advanced aerodynamic design and efficient motor systems provide stable and efficient air flow in various production processes. By optimizing airflow distribution and reducing energy loss, the Shuangjian blower can significantly improve energy efficiency.

Rigorous process to ensure reliable performance of equipment

Shuangjian blower adopts strict standards and measures in quality control. From raw materials into the factory to finished products, every link has undergone strict quality testing and monitoring. Through advanced testing equipment.

International high standard configuration

High quality accessory selection and reliability design provide sufficient equipment strength and durability for the Shuangjian blower, and reduce maintenance costs. Selection of domestic and foreign well-known brand accessories.

Easy maintenance to improve equipment operation rate

The fan is equipped with sliding bearing, thin oil station, high fuel tank and a complete set of safety interlock protection system, and the shell is horizontally divided, and the fan inlet and outlet pipes are horizontally connected with the shell inlet.

Digital processing, higher precision

Hubei Shuangjian has dozens of CNC machine tool production lines and robot welding equipment, from steel plate cutting, bending, planing, milling to painting, all realize digital control, high processing precision, some core components accurate.

Original parts supply, running worry free

Hubei Shuangjian as a set of production and sales in one of the strength of the enterprise, we are responsible for their production of each piece of equipment, to provide customers.

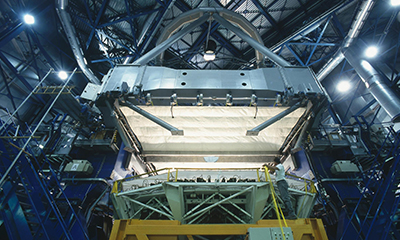

Product Details

The Centrifugal compressor is to increase the pressure of the gas, and the gas passes through the impeller due to the high-speed rotation of the impeller, the gas is subjected to the effect of centrifugal force to produce pressure. In recent years, with the promotion of new metallurgical technology, the expansion of the scale of petrochemical enterprises and the rapid development of new coal chemical industry, green coal power and other industries, the number and scale of air separation equipment requirements are increasing. The large scale of air separation equipment is the direction of development. In order to cooperate with the market development, Hubei Double sword from 2002 began to devote to the research of air separation compressor unit, in order to ensure the advanced nature and reliability of the unit, we with many domestic scientific research institutions and efficient technical cooperation, developed an energy-saving and environmental protection double sword series supercharger, mainly used in petroleum, chemical industry, metallurgy, coal, medicine, air separation, power, textile and other fields.

Compressor main components

· Air compression components: impeller, diffuser, volute

· Gear transmission components: gears, bearings

· Sealing parts: oil seal, gas seal, oil and gas isolation

· This series of compressors belongs to the medium and low pressure series, which can implement single stage, two stage and three stage compression in a single cylinder, and can also pump or add gas from the cylinder. 2-10 impellers can be arranged in a single cylinder, and a multi-cylinder unit can also be formed. This series of compressors is from Italy's NUOVO PIGNONE S.P.A. imported technology.

· Air compression system, cooling system, lubrication system and control system inherit an integral structure.

· High aerodynamic efficiency to achieve aerodynamic effects, impeller efficiency of more than 92%.

· Mature multi-shafting rotor design for rotor stability and bearing load.

· The key core components (gears, bearings, seals, oil pumps, filters, oil coolers, monitoring elements, monitoring components, etc.) are all made of internationally renowned brands.

· Standard module design, convenient maintenance.

· Intuitive control interface, easy to read and operate.

· Provide comprehensive technical service support to customers.

Product Atlas

Product Parameters

Technical parameter

· Flow range: Q=20-9000m3/min

· Maximum working pressure: Pc=4.5mpa

· Working speed: n=3000-18000r/min

·Shaft power: n≤25000kw

Maintenance

1. Daily inspection and maintenance

Appearance inspection: Check the appearance of the blower regularly to confirm that there is no damage, deformation or rust.

Running sound: Monitor the running sound of the blower. If there is abnormal sound, stop the machine immediately for inspection.

Vibration: Check the vibration of the blower regularly to ensure that it is within the allowed vibration range.

2.Lubrication system maintenance

Lubricating oil inspection: check the oil level and quality of lubricating oil regularly to ensure that it is within the specified range, and replace the deteriorated lubricating oil in time.

Grease replacement: For the parts that use grease, it is necessary to replace it regularly to ensure the lubrication effect.

3.Cooling system maintenance

Cooling water inspection: For the blower with water cooling, it is necessary to regularly check the flow rate and temperature of the cooling water to ensure that the cooling effect is good.

Cooler cleaning: Clean the cooler regularly to prevent its blockage affecting the heat dissipation effect.

4.Internal inspection and maintenance

Internal cleaning: Regularly clean the dust and debris inside the blower to avoid damage to the blower.

Fastener inspection: Check the fasteners inside the blower to ensure that they are tight and not loose.

5.Electrical system maintenance

Motor inspection: Check the running status of the motor regularly to ensure its normal operation.

Cable check: Check the connection and insulation of the cable to ensure that there is no damage or aging.

6.Shutdown and maintenance

Shutdown cleaning: When the blower is shut down, thoroughly clean the dust and dirt inside and outside the blower.

Downtime inspection: Use downtime to conduct a thorough inspection of the blower to find and deal with potential problems.

Through the attention and execution of these maintenance details of the blower, it can ensure its long-term stable operation, extend its service life, and improve production efficiency.

Design and development capability

Our company has strong technical research and development capabilities, and has established several research workstations to bring sustained vitality to the improvement and progress of Shuangjian's technical research and development capabilities.

Strict testing

Supporting auxiliary support technology and functional control technology for modern design and manufacturing of new wind turbines, establishing a network CAD system, using deformable simulation analysis software to achieve intelligent product design and process design.

Quality assurance

Our company has developed dozens of quality management documents in accordance with the requirements of the ISO9001:2000 quality management system, including the Quality Manual, Procedure Documents, Incoming Inspection Specification, Process Inspection Specification, Finished Product Inspection Specification, Equipment Operation Regulations, Assembly Operation Manual, and Test Equipment Operation Manual.

.jpg)

.jpg)

.jpg)